Lubricant efficiency

Unlocking the Secrets of Efficient Lubrication in Metal Cutting

We embarked on a journey to gain a deeper understanding of how lubricants impact metal cutting processes. To do this, we partnered with Ecolubric, who has dedicated decades to the development of highly efficient lubricants. Ecolubrics unique blend, produced in Västerås, Sweden, consistently outperforms others on the market – test results show a clear margin of improvement.

With Ecolubrics expertise and our diagnostic method, we wanted to answer two questions:

- How can we create even more value with our solution?

- What new insights can be gained that help us and others better understand the role of lubrication in machining?

Why lubricants matter in machining

Lubricants play a decisive role in metal cutting. They influence efficiency and tool life through three key mechanisms:

- Cooling: dissipating the heat generated in the cutting zone.

- Friction reduction: forming a liquid film between tool, workpiece, and chip.

- Chemical prevention: blocking reactions that create adhesive bonds and damage the cutting edge.

In particular, when machining difficult-to-cut materials at low cutting speeds, preventing chemical reactions becomes critical. Without the proper lubricant, adhesion can quickly destroy the cutting edge and compromise the process.

Minimum Quantity Lubrication

A promising approach is Minimum Quantity Lubrication (MQL), a technique that delivers a fine mist of oil droplets – sometimes as small as 2 µm – directly into the cutting zone. Unlike traditional flood cooling, MQL uses only tiny amounts of fluid, making it both efficient and sustainable.

Our diagnostic method revealed striking differences between dry milling and milling with MQL. Without lubrication, the process produces dense, clustered sound patterns, a sign of adhesion and stress on the tool. With MQL, the sound changes – clusters become more distinct. This is a clear indicator that adhesion is reduced and tool life is supported.

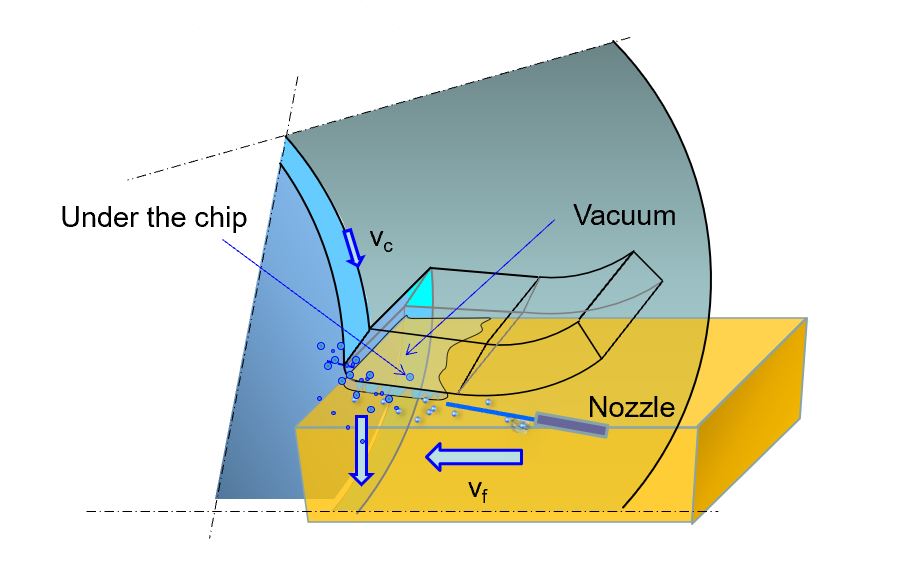

The explanation lies in the mechanics of the cutting process: vibrations and chip segmentation create micro cavities between the tool and chip/workpiece material. These cavities act like vacuums, pulling in the fine lubricant droplets (see Fig. 1). Once inside, the droplets reduce adhesion, dissipate heat, and may even form protective films at high temperatures. In effect, MQL allows the process to “speak” a different language – one of smoother, more efficient cutting.

Fig 1 Lubrication mechanism

From diagnostics to deeper understanding

By using sound-based diagnostics, we can decode the hidden story of machining. It is not only about whether a lubricant works, but also about how it works. The ability to interpret these subtle signals opens new possibilities for:

- Sustainability – cutting fluid use is minimized while maintaining performance.

- Cost-efficiency – extended tool life, reduced cutting fluid cost, and reduced downtime.

- Knowledge building – understanding the fundamental mechanisms that govern machining.

Conclusion

Lubrication might seem like a small detail in the complexity of metal cutting, but it has a transformative impact. The right blend, applied in the right way, can completely change the behavior of the process. By combining deep expertise in lubricant formulation with our advanced diagnostics method, we can not only optimize machining but also uncover new insights into the very language of cutting.

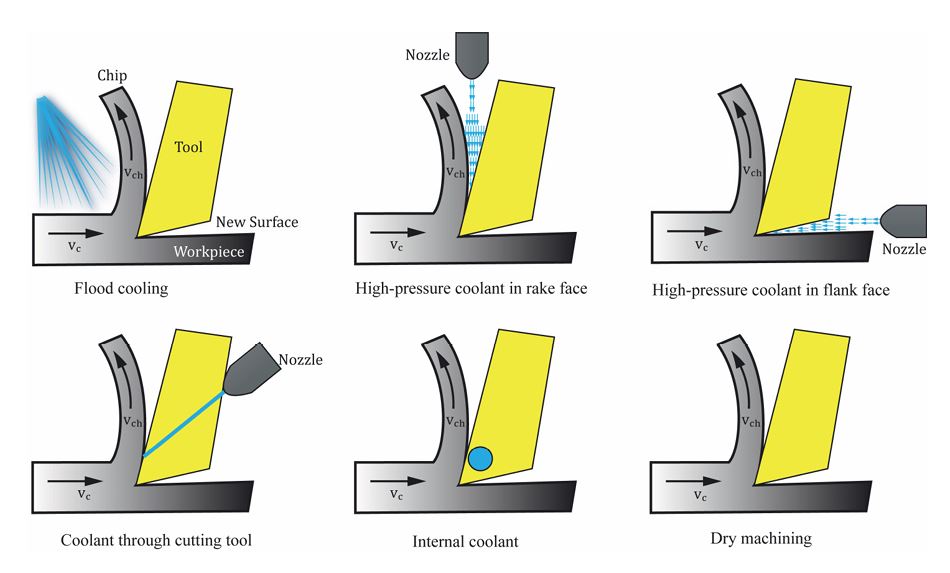

Fig 2. Overview of the different strategies of coolant application in machining (Tamil Alagan, 2019).

We sincerely thank Ecolubric for their collaboration on this journey and for providing us with Tamil Alagans illustration above (Fig 2). If you are interested in learning more about Ecolubrics products, please reach out to them directly. If you would like to know more about our in-process diagnostic solution and how we create value in machining processes, you are welcome to contact us.

Authors of this article; Stefan Magnusson, Kourosh Tatar and Inge Svenningsson.

Recent Comments